1 / 25

- Here to talk about my work to help make it easier to replicate electronics projects

2 / 25

- Let me give you a quick overview of how you can make electrinics.

- You have a printed circuit board, typically made of fiber glass and copper tracks

- You could try and etch these yourself but they have become very affordable to order in the past decade.

- So you have this board, often shortened to PCB And you have components, with legs or pins, that you solder on by careful application of heat and solder wire

Through-hole

3 / 25

- You can have through hole components where the legs stick through a hole in the boord

Surface mount technology (SMT) or Surface mount device (SMD)

4 / 25

- And you can have surface mount components, which are often shortened to SMT or SMD

Reflow soldering

5 / 25

- If you are making more than one board, or you have very tiny surface mount components you typically want to use a reflow process.

- You apply solder paste, site the component on top and heat it up.

- Often people hack toaster ovens to have more control over the temperature curve

Printed Circuit Board Etching

6 / 25

- But of course, this get tedious so etching connections into copper-clad fiberglass can be much less tedious

- You can do this at home, you print onto a copper-clad board which will resist an acidic bath and leave you with just the connections that you want

Gerber Files

7 / 25

- What you are looking for in an OSHW project are the gerber files

- These describe the printed circuit board design

- And what you'll find if you look at the gerber files of a typical OSHW electronics project

- You will see multiple layers

- Tiny drills

- A solder resit and a silkscreen layer

8 / 25

- So, for these you really need an industrial process

- On the whole they use a similar etching process to what you can do at home but they have a lot more accurary and they have further steps which are harder to do at home

- You get a nice silkscreen or ident layer which help you see where components are supposed to go, you get solder resist which helps you keep the solder where it needs to be

- You have much more accurate drillng and the drills themselves are internally plated through electro-plating, so they can make connections between layers

- And you can have many more layers laminated together

PCB Batching Services

9 / 25

- And it's cheap

- There are so many places where you can order your PCBs these days and get them within a few weeks for under 20 euros, it's pretty insane compared to 10 years ago

Learn more at your local hackspace!

10 / 25

- If you are interested in doing this, you should check out your local hackspace and learn how.

- Here in bristol we have a modified toaster oven and plenty of friendly people that are willing to show you how to use it.

- We also have a lot of other cool tools like a laser cutter and 3d printer, go check us out on the web!

11 / 25

- The way to design these boards is to use a schematic entry and a PCB layout software.

- You draw out a schematic, which is a sort of map where you want all your connections to go.

- And then place them onto a model of a board and route the connections your previously defined

- Once you make a design you can share this with people, and in theory someone should be able to replicate it.

- So that's what we call open hardware.

Open hardware is growing!

Feb 2017:

- ~3000 KiCad projects on GitHub

- ~7000 Eagle projects on GitHub

- ~9000 shared projects on OshPark

Oct 2017:

- ~5500 KiCad projects on GitHub

- ~12000 Eagle projects on GitHub

- ~13000 shared projects on OshPark

Hackaday.io, blogs, etc...

12 / 25

- And it's growing!

- I gave a presentation at FOSDEM in febuary and took a rough survey and did the same again last week

- And there are other places to put up projects as well

- So what's the problem?

13 / 25

- The problem

- The problem is that it's hard to document electronics in a way that allows others to replicate them

- Often it takes considerable effort to understand someone else's work

- Projects can be simultaneously brilliant but not reproducable

- There is no clear standard way to present the information that reduces the friction

14 / 25

- So what we would like, is something that incorporates all these different ways of doing things

15 / 25

- Allows you to make the PCB

16 / 25

- And allows you to purchase the parts

17 / 25

- And this is my approach to try and solve this

- The Kitspace.org web service

- and the 1-click BOM browser extension

1-click BOM extension

Automates purchasing by replicating the web requests that are sent when you use retailer sites:

- Digikey

- Mouser

- RS

- Newark / Farnell / Element14

18 / 25

- The browser extension tries to completely reduce the friction between a BOM and the retailer shopping cart

- It does this by replicating the web requests that your browser sends when using the site

- Currently works for these retailers

1-click BOM extension

- Available for Chrome and Firefox

- Takes in tab separated values (the clipboard format of spreadsheet programs)

- Can load a online BOM

- Able to add to and remove from cart

- Can have a guess at what part you mean

- Open source (CPAL)

- About 600 users

19 / 25

20 / 25

21 / 25

- So this kind of solves one aspect of our goal.

- We can replicate purcheses across the globe

- But it doesn't include the PCB and there is no standard way to package a complete project to be replicated

Kitspace.org

- Git repository

- Tab separated values

- 1-click-bom.tsv

- At minumum: References, Quantity and Part Number

- RS274-X Gerbers and Excellon drills

.├── 1-click-bom.tsv└── gerbers ├── board.cmp ├── board.drd ├── board.dri ├── board.gko ├── board.gpi ├── board.gto ├── board.stc └── board.sts22 / 25

- So this is where kitspace.org comes in.

- We combine the BOM with gerber files and put the in a Git repository

- And kitspace.org makes a page out of this for people to access

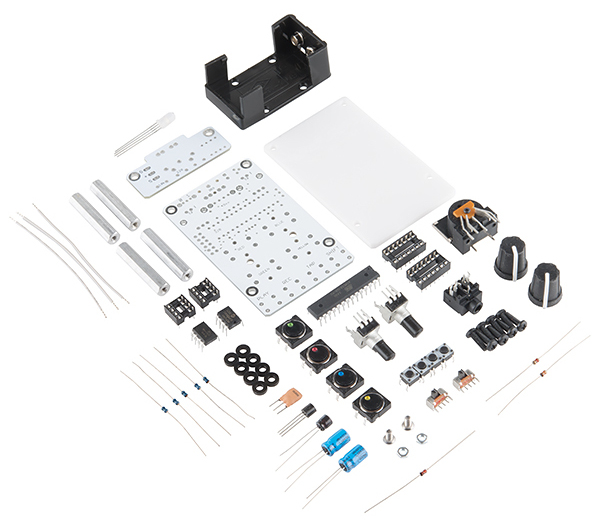

Kitspace.org: The Virtual Kit

24 / 25

The idea really is that, creators can put together a virtual kit, that others can buy themselves, and we can share open hardware designs that way. With the least amount of friction.

So I want to encourage you, to check out your local hackspace. If you are from around here that's the bristol hackspace, there

Questions?

- kitspace.org

freenode#kitspace/#kitspace:matrix.org- @kitspaceorg

- github.com/kitspace/kitspace

Image credits

- ALL ABOARD - James Turner, https://spectrum.ieee.org/geek-life/hands-on/build-a-customprinted-circuit-board/1

- http://ch00ftech.com/2013/06/11/getting-itty-bitty-with-the-ice-breaker-2-0/

- Cover of Troubleshooting Analog Circuits by Robert A. Pease - © 1991 by Butterworth-Heinemann

- Meat grinder & Disassembled hand-powered grinder - CC-BY-SA Kku and Rainer Zenz

- Bleep Drum Kit with MIDI - CC-BY-SA SparkFun Electronics

25 / 25